+86 10 5248 4022

+86 18518927929

Oct. 26, 2023

Discover the versatility of unistrut connections for all your structural needs. With a wide range of connection options available, you can easily customize and adapt your construction to meet your specific requirements.

Unistrut connections play a crucial role in various construction and engineering projects. Unistrut, a brand known for its metal framing system, offers a versatile and reliable solution for creating sturdy and adjustable structures. In this article, we will explore the different types of Unistrut connections and their applications, highlighting their benefits and providing practical insights for successful installations.

1. Types of Unistrut Connections:

1.1. Channel-to-Channel Connection:

This connection involves joining two Unistrut channels end-to-end or side-by-side. It is commonly used to extend the length or width of a structure. Various methods can be employed, such as channel nuts and bolts, beam clamps, or splice plates.

1.2. Channel-to-Channel Angle Connection:

When two channels meet at an angle, this connection is used. It provides stability and strength to structures requiring angular support. Angle fittings, brackets, or corner connectors are commonly utilized for this connection.

1.3. Channel-to-Channel T-Connection:

In scenarios where one channel intersects another at a right angle, a T-connection is employed. It allows for the creation of perpendicular structures and provides additional stability. T-fittings, angle brackets, and cross connectors are typically used for this connection.

1.4. Channel-to-Channel Cross-Connection:

When two channels intersect perpendicularly, a cross-connection is used. This connection is ideal for creating grid-like structures or adding support at intersecting points. Cross connectors or four-way connectors are commonly used for this connection.

2. Benefits of Unistrut Connections:

2.1. Flexibility and Adjustability:

Unistrut connections offer the advantage of adjustability, allowing for easy modifications during installation or future alterations. This flexibility ensures adaptability to changing project requirements.

2.2. Strength and Durability:

Unistrut connections are known for their high load-bearing capacity and durability. They provide reliable support for various applications, including HVAC systems, electrical installations, and industrial equipment.

2.3. Cost-Effectiveness:

Compared to traditional welding or fabrication methods, Unistrut connections offer a cost-effective solution. They require minimal labor and tools, reducing installation time and expenses.

3. Practical Tips for Successful Unistrut Connections:

3.1. Accurate Measurements:

Ensure precise measurements to determine the required length, angle, or intersection point for each connection. This step is crucial for achieving a proper fit and alignment.

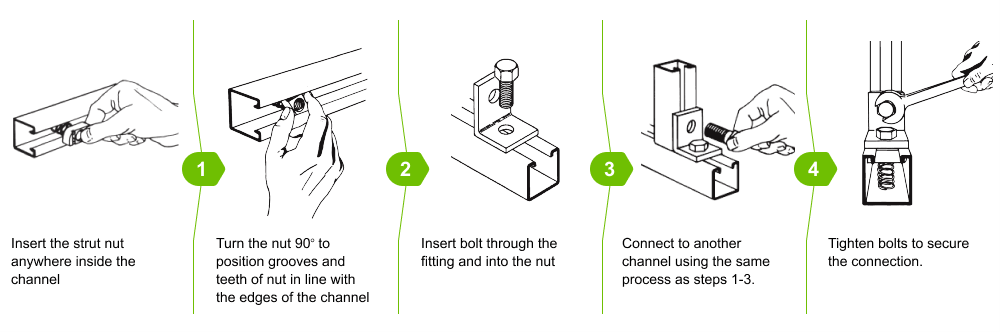

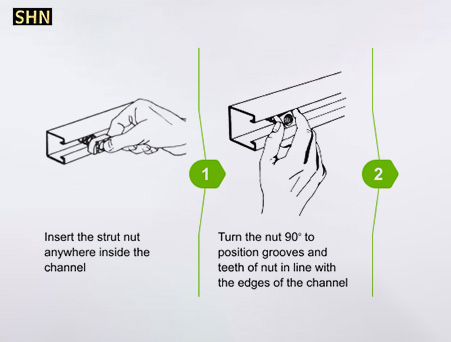

3.2. Proper Fastening:

Use appropriate fasteners, such as bolts, nuts, or screws, and ensure they are tightened securely. This step guarantees the stability and integrity of the connection.

3.3. Regular Inspections:

Periodically inspect Unistrut connections for signs of wear, corrosion, or loose fasteners. Timely maintenance will help prevent potential issues and ensure long-lasting performance.

Unistrut connections offer a versatile and reliable solution for constructing robust structures in various industries. Understanding the different types of connections and their applications, along with following practical tips for successful installations, will contribute to the overall success of your project. With their flexibility, strength, and cost-effectiveness, Unistrut connections are an essential component for any construction or engineering endeavor.

Slotted Channel - for light structural support

Dec. 11, 2023How to Attach slotted channel to a Beam?

Dec. 11, 2023Leave Message

Write down your urgent needs to get free samples, and to check our stocks

Copyright © SS&HN INDUSTRY GROUP Ltd. All Rights Reserved | Sitemap | Powered by